SERVICES | VIBRATION

The word “vibrate” is defined as “resonate; sound with resonance”. The study of sound and vibration are closely related. Sound, or “pressure waves”, are generated by vibrating structures (e.g. vocal cords); these pressure waves can also induce the vibration of structures (e.g. ear drum). Hence, when trying to reduce noise, it is often a problem in trying to reduce vibration.

-

Shaft Power/Torsional Vibration

Torsional vibration occurs commonly in any object which turns or twists as it refers to angular vibration along an axis of rotation. It is a primary concern in power transmission systems using rotating shafts or couplings as failures can occur if not properly controlled. In ideal power transmission systems, the torques applied or reacted on the rotating parts should be “smooth”, leading to constant speeds. However, in reality, the torques generated may not be smooth (e.g., internal combustion engines) or the component being driven may not react to the torque smoothly (e.g., reciprocating compressors). Also, the components transmitting the torque can generate non-smooth or alternating torques (e.g., worn gears, misaligned shafts). Due to the limitation in the stiffness of the components, the alternating torques caused vibration along the axis of rotation. -

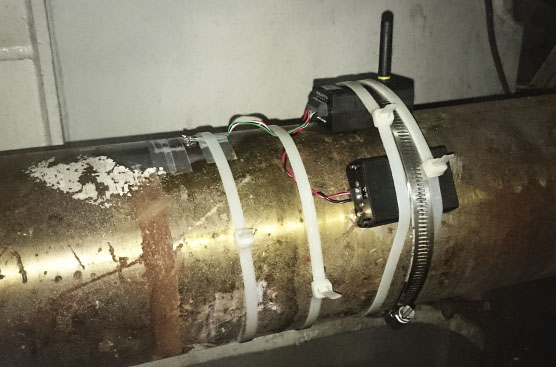

Vibration Condition Monitoring

Vibration condition monitoring (VCM) refers to the process whereby vibration data of a machine is monitored on a regular basis in order to establish a trend, and thereby, key symptons of mechanical faults such as imbalance, misalignment, looseness and bearing faults etc. can be easily identified, corrected and/or prevented. -

Industrial Vibration Control

Industrial Vibration Control refers to the control of vibration in industrial situation or equipment, preventing implications such as mechanical failure, malfunctioning, or noise problems. It is commonly conducted in tandem with a vibration condition monitoring program. -

Vibration Design and Analysis

Vibration refers to mechanical oscillations about an equilibrium point. Vibration is sometimes “desirable”, as in the form of the motion of a tuning fork, the reed in a woodwind instrument or harmonica, or the cone of a loudspeaker. Vibration is necessary for the correct functioning of the various devices. However, often, vibration is undesirable, energy-wasting, creating unwanted sound in the form of noise as in the vibrational motions of engines, electric motors, or any mechanical device in operation. Such vibrations can be caused by imbalances in the rotating parts, uneven friction, the meshing of gear teeth, etc. Meticulously-designed machinery with vibration in consideration have less occurence of such problems. Vibration analysis enables early detection of mechanical failure, allowing the machinery to be repaired or replaced before an expensive failure occurs.